|

Least Resistance Training Concepts

|

|

Part Three

When anchoring with rope or webbing, remember "Wrap 3, Pull 2".

|

| Basic Pulley Systems |

|

The typical pulley systems for "load and go" operations involve what are generally known as "Z-rigs." Basic Z-rigs provide a 3:1 mechanical advantage. These layouts can be compounded to provide greater mechanical advantage but the purpose of this information sheet is to present quick and simple equipment layouts.

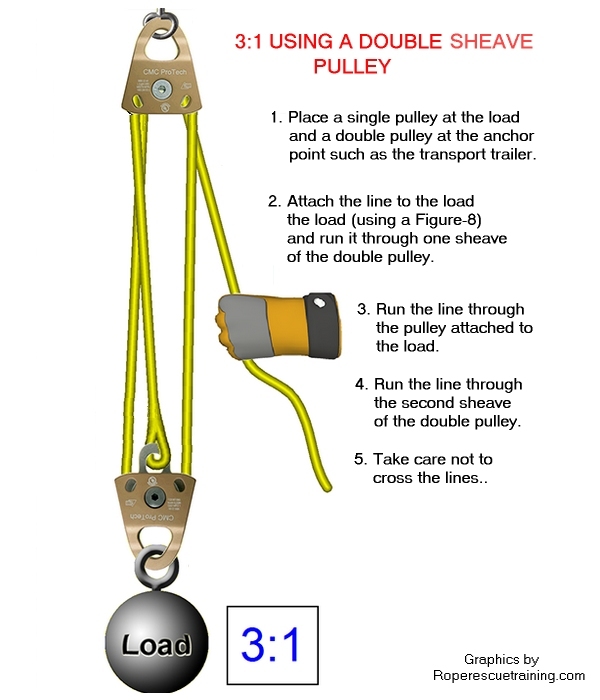

Z-RIG WITH ONE SINGLE SHEAVE AND ONE DOUBLE SHEAVE PULLEY The single pulley is connected to the load while the double pulley is connected to the anchor point. When hooked up the line runs from a hard attachment at the load (usually using a carabiner,) through one sheave of the double sheave pulley, then through the single sheave pulley back at the load, then through the other sheave of the double sheave pulley.

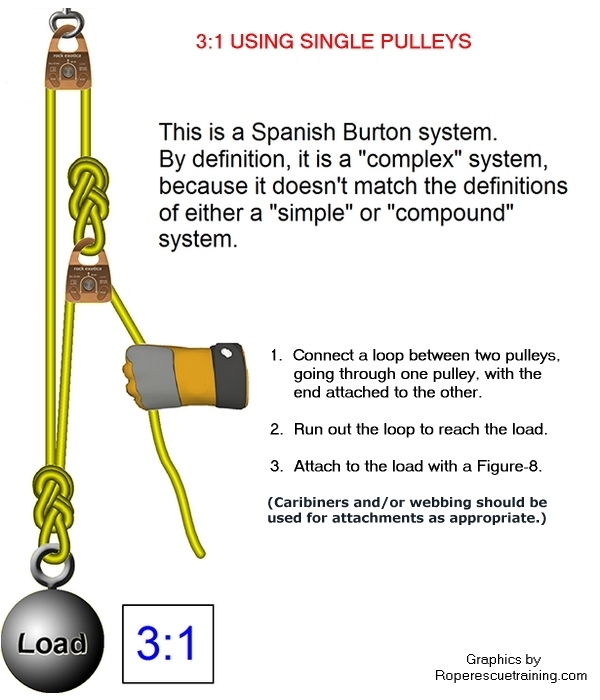

Z-RIG WITH SINGLE SHEAVE PULLEYS A Z-rig can be created using single sheave pulleys if a double pulley is not available. This system tends to use up more rope, so using a double sheave pulley at the anchor point is more efficient.

|

Continue to Carabiner Key Points

Return to Part Two

Return to Information Sheets and Resource Guides

Return to Sample Incident Responses

Return to LRTC TLAR / EVAC Page

The training information presented in these information sheets and guides is offered for illustrative and volunteer refresher purposes only. It is not a substitute for actual hands-on training. |